Repurposing Empty Skyscrapers Into Urban Farms

With the second wave of the COVID-19 pandemic upon us and teleworking being more popular than ever, office buildings in several North American cities are deserted. The occupancy rate of office towers in major Canadian and American cities has never been so low, reaching only 25% in some areas.

Workers aren’t the only people deserting downtown areas since the pandemic hit; more and more city-dwellers are also moving to smaller and rural municipalities. For example, Manhattan had 15,000 empty apartments last august, a new record! Even more surprisingly, many real estate developers and builders continue to erect commercial buildings. But who will occupy these skyscrapers?

What if we gave unoccupied buildings and skyscrapers a new purpose by converting them into urban farms? Read on to see why this project is so relevant and doable!

(credit: Konodesigns): Located in the heart of Tokyo, the Pasona Group building houses a vast indoor urban farm.

Indoor farming More Productive Than Greenhouse Culture

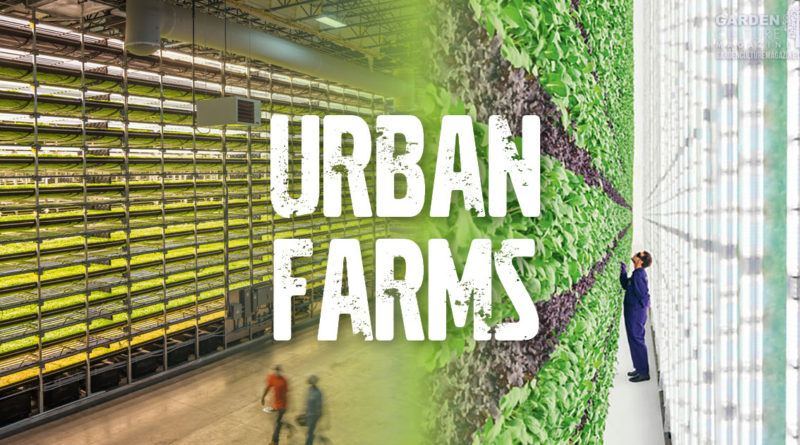

Growing vegetables does not have to be done outdoors, in-ground, or in greenhouses. Large-scale urban agriculture can be practiced inside buildings, without even having sunny windows for light. However, the inner envelope of buildings must be waterproofed to protect them from any mold. It is also necessary to equip grow rooms with proper ventilation and LED lighting systems specially designed for growing plants.

Despite these essential modifications needed for an urban farm, the fact remains that the indoor farm’s productivity is much higher than that of greenhouse crops. Inside a building, it is possible to grow plants vertically and increase the growing area. This concept isn’t feasible in a greenhouse without blocking the sun from the plants below. It is estimated that an indoor vertical urban farm can produce up to eight times more food per square meter than a greenhouse. If well insulated, an existing building is significantly less expensive to heat than a double-walled glass greenhouse.

Indoor Urban Farms

The largest indoor urban farm in North America is located in Newark, New Jersey. AeroFarms is inside a building that housed a former steel mill. This farm uses 95% less water than a conventional farm and provides about 30 harvests of leafy vegetables per year for every square meter of crops.

(credit: Aerofarms): Around $30 million has been invested in AeroFarms to repurpose a building that housed a former steel mill into a state-of-the-art urban farm.

Another urban farm project called Pasona Urban Farm began a few years ago in Tokyo, Japan. Pasona Group Company grows edible plants in a nine-story building.

Significant renovations to the existing superstructure included adding a green facade, offices, an auditorium, cafeterias, a rooftop garden, and most importantly, indoor urban agricultural facilities.

The crop space totals over 43,000 square feet with 200 species grown including fruits, vegetables, and rice. Crops are harvested, prepared, and served in the building’s cafeterias. Pasona Urban Farm is the largest urban farm-to-table agricultural project ever in an office building in Japan.

(credit: Konodesigns): The indoor growing areas of Pasona Urban Farm have been created with obvious aesthetic concern. A section of the building is entirely dedicated to rice cultivation.

Several dozen urban agriculture start-ups have been founded in recent years. The German company Infarm is a firm specializing in the conversion of old buildings into urban farms with a bright future.

(credit: Infarm) Infarm’s growing system is easy to set up and quickly transforms any office building into an indoor city farm.

Another example is California-based urban agriculture firm Plenty, which recently raised more than $200 million in funding, in part provided by Jeff Bezos, CEO of Amazon.

(credit: Plenty) The indoor urban farms created by the California-based company Plenty use a vertical aeroponic system that requires very little space.

Locally-Produced Food

With rapid urban sprawl, food for city-dwellers is being produced further and further away, thousands of kilometers from where it is finally eaten.

Food must be transported to cities by plane, train, or truck, generating large amounts of pollutants and greenhouse gases. According to the Worldwatch Institute, the food that makes up a typical North American plate is transported an average of 2,400 kilometers before being eaten.

Transporting and storing food also forces farmers to grow varieties of fruits and vegetables that are firm, contain little juice, and have very thick skins so they can withstand frequent handling, shock, and temperature variations.

The UN’s Food and Agriculture Organisation estimates that 45% of all fruits and vegetables produced around the globe are lost or thrown away before being eaten, and this, in part, is because of food transport and handling.

Creating indoor urban farms in buildings is an excellent idea, especially if food is sold locally and if citizens are involved in the management of these businesses.

Albert Mondor

Passionate about environmental horticulture, urban agriculture, and extreme landscape design, Albert Mondor has practiced his craft for over 30 years and created numerous gardens in North America. In addition to teaching courses and lecturing at conferences across Canada, his weekly gardening column appears in the Journal de Montréal and the Journal de Québec since 1999. Albert recently published his tenth horticultural book, Le nouveau potager. He is a regular guest and contributor to radio and TV programs and hosts The Trendy Gardener spots broadcasted on Météo Média and online. In May 2014, Albert was awarded the prestigious Henry Teuscher Award, presented by the Montreal Botanical Gardens for his exceptional contribution to the advancement of horticultural knowledge in Canada.

Latest posts by Albert Mondor (see all)