Achieving Ideal Airflow In Your Grow Room

You are not alone if you struggle to understand perfect airflow in your room. I have designed 100+ grows, extraction facilities, and GMP spaces, and airflow is typically one of the most crucial factors in all applications. I must always consider each room and each application to determine the best options. There are many different ways to get ideal airflow. However, much of that can depend on your application and what you are trying to accomplish. As with many aspects of indoor growing, there are many ways to resolve airflow. We will start with the ideal scenario, which, unfortunately, is also generally the most expensive solution. Then, we can discuss other options and logic for solving the problem more efficiently.

Why Is Airflow Important?

Before finding ways to solve or distribute the air, we should consider why we are trying to be so specific with airflow and its effects on your rooms and plants. As with all grow rooms, airflow helps dictate the microclimates in each space. Microclimates form due to specific elements, such as moisture, cooling, dehumidification, and light sources. For a microclimate to occur in a room with good airflow, you must have something causing the issue. Proper airflow ensures that all plants see the same climate conditions and can transpire at the same rate for optimum plant growth. Places in the room that are too hot, cold, humid, or windy will cause plants to grow unequally and affect plant health. Ideally, a grow will have evenly distributed air so all plants have the same opportunity to grow uniformly.

The Perfect Situation

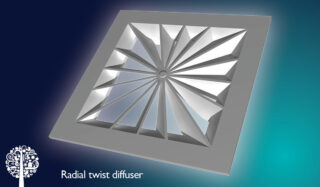

The perfect grow room airflow comes from the designs used in the GMP pharmaceutical world. These designs have been used for many years to create a uniform, clean room. With Stratus Designs, we have taken a twist (pun intended) to this approach, removed the typical laminar diffusers, and switched them to radial twist diffusers. The air in these applications is distributed overhead in the primary air handler. The overhead distribution for indoor growing works well, as the main sources of heat gain to the rooms are the lights. To cool space, you need to deliver air colder than you are trying to achieve. If you want 80°F in an area, you may have to deliver at 65-70°F to maintain those conditions.

The beautiful thing about overhead air distribution is we can get the heat from the lights out at the source and not have it radiate down onto the plants as much. We can also ensure we don’t have freezing air directed right onto the plants. With the radial twist diffuser, we mix the air at the source and add turbulence above the light fixtures to help break the microclimate barrier that forms. The twist diffuser successfully blends the air and creates a better growing environment. In this perfect situation, we do a low-level return (how the air gets back to the air handler), resulting in a uniform room. Bottom returns are ideal, as all the clean air comes from the top and “pushes” all the dirty air down to the low returns. The air is then sucked up and returned to the air handler for filtration, treatment, and redelivery. With bottom returns, it is essential to do about 10 feet of stainless steel duct so that when washing the floor, you don’t risk splashing water in and rusting the bottom of the duct out. With a top supply and bottom return, you will get a beautiful room with very uniform plants. While this is typically a very high-end design, I suspect some clever home growers can modify their rooms and accomplish this simpler than full, in-wall return grills.

The Price Is Right

In designing these spaces, I’m constantly asked for a more cost-effective solution to ducting distribution. From my experience, there is no substitute for bottom returns. However, we have had success with another distribution type and fans. This type of distribution is also with radial twist diffusers. However, rather than many low returns grills, we use one large return low near the back of the room or closest to the air handler. This idea saves money and room space, as walls don’t need to be 12-18″ thick to install ductwork. The issue with the single return is the front of the room often doesn’t quite get the airflow we want. In these applications, the client must install in-room fans to add supplemental movement in the spaces. I typically recommend fixed-direction fans with speed control. Renegade makes good low-cost EC (electronic current modulation) fans that are speed-controlled and energy-efficient. In these types of installs, I recommend that clients take the air and blow it to the front of the room, away from the return grill. The reason for this is the return should be the lowest pressure point in the room, which means the air tends to want to go to that side. By blowing the air to the front of your room, we can create extra movement, helping minimize microclimates. The only thing the same about all rooms is they are all different, so don’t be afraid to experiment and see how your plants behave.

I should note that I don’t like to return air from the ceiling in all applications, as it doesn’t allow proper air circulation and can often lead to short air cycling. I have done this before, and it can work, but it is not ideal.

Other Types Of Grows

The two options above are my typical design for air handler-based grows. However, what about grows with mini-split AC/Heat pumps? This type of design gets more complicated in determining the best distribution; you have little to no flexibility regarding where your supply and returns in a room go. Your only option is the indoor unit head placement and height. I always mount my mini-splits at the light height or higher. I do this as the cold air from my mini-split will fall, and I want to pick up the hot air at its source. Unfortunately, the return on the mini-split is now up high, and mixing becomes an issue again. With my mini-split projects, I try to space them evenly throughout the room and avoid microclimates by strategically placing fans. I find my handheld psychrometer (which measures temperature and humidity) to ensure my rooms are uniform. Again, I use EC fans and modulate fan speed to get the perfect plant movement.

Airflow is vital to plant health. Plants need wind to grow strong and to help mix the air in a space. Without proper airflow, you will have a hard time growing great plants. Your ladies want to dance a little to transpire just right. Make sure you spend plenty of time in a grow room during all stages of growth to adjust your fans accordingly. Good airflow means healthy plants, and healthy plants make you happy.