LED Technology Causing a Resurgence in Light Lifting Practic

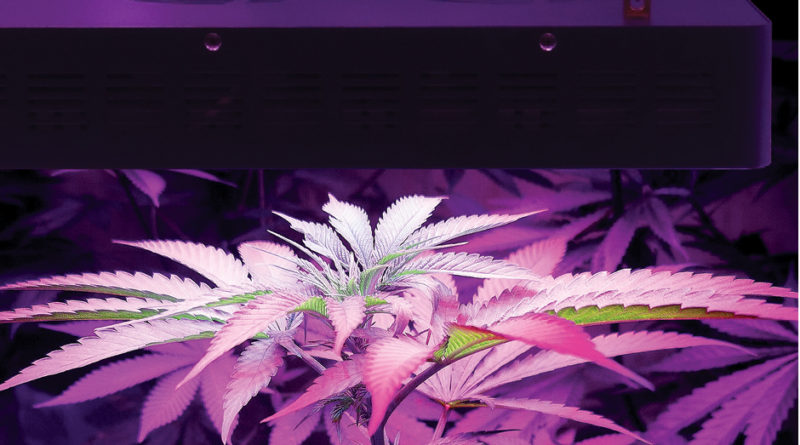

Perhaps no area of modern cultivation tech has witnessed the sort of upheavals as horticultural lighting. Each new advancement in grow light technology seemingly gives rise to a kaleidoscope of new methodologies for cannabis growers. As such, any well-seasoned indoor grower will likely tell you that their lighting setup and subsequent grow room have changed several times over the years.

Within these ever-changing fields of technology and cannabis cultivation, we consistently reassess the need to raise and lower grow lights. As a result, we see a huge divergence in light positioning processes between DE HPS and LED growers.

It can’t be denied that Gavita ushered in the double-ended HPS revolution. With the rise of their lighting technology, growers reveled at the idea of not having to move lights anymore. According to Gavita, their lights should be positioned three to five feet above a garden canopy — this distance is relative to variables such as light grid and room size. Notably, Gavita also states “lights do not need to be lowered or raised.”

Just as DE HPS technology took the cannabis space by storm, LED lights were beginning to infiltrate on the fringes of the scene. For many growers, LED technology is attractive because the lights use relatively little electricity and operate at cool temperatures. Needless to say that both these factors offer a serious leg up on heat-producing, energy-gobbling DE HPS.

As growers now migrate towards LED technology, they again have to accept the fact that they need to raise and lower their lights. To help us understand the benefits of LED growing, as well as the trials of light lifting, we reached out to a couple of indoor cultivators for a quick Q&A session. For starters, we spoke with Chris Watt, the Cultivation Director from True Organics in Michigan. True Organics produces indoor craft flowers through traditional organic soil growing. We also spoke with Mike Miller in British Columbia, Canada. Mike chose to keep his company private but was very informative in our conversation.

Maximum Yield: What sort of lights do you use?

Chris Watt: We use Venntis Technology LEDs and hang them 12-18 inches above the canopy. Not only are these lights cost-effective with electrical usage and energy rebates, but they also produce high-quality flowers at a low canopy temperature. We feel they are way better than DE lights overall, they are the way to go.

Mike Miller: We are using Fohse LED lights. Our operation has only been using them for a few weeks, but so far we are happy with the results.

MY: Do you raise and lower your lights?

CW: Yes, we move our lights. However, there are some challenges. According to Michigan fire code, commercial growers can’t use yo-yos, so we must work with metal hangers. To consistently move lights with these hangers is very time consuming, and also leads to increased contact with the canopy and potential microbial infections.

MM: Yes, we keep them 1.5 feet away from the canopy. If they are too far away from the canopy, they will stretch the plants. However, moving them can be a real issue.

MY: On what information are you basing your decision to move your grow lights?

CW: A combination of personal experience and factory specs. Depending on the size of the garden, you should keep these LEDs anywhere from 12-18 inches above the canopy. However, if you don’t pay attention for a few days, you can do some serious damage.

MM: Experienced growers can tell when to move their lights by looking at their garden. In essence, the plants tell you when to move the lights.”

MY: Have you witnessed the negative impacts of improper grow light spacing?

CW: Yes, I have in a few different ways. First of all, if the tops of cannabis plants grow too close to LED lights, the tops will get bleached out. Also, I have seen poor quality metal light hangers malfunction and cause lights to fall on plants.

MM: Yes. If lights are too close, they will start to burn and wilt a little bit. If they are too far away, plants will stretch to reach available light.”

Horticultural lighting has seen a number of technological revolutions over the past 15 years. Currently, DE HPS and LED lights are at the forefront of the industry — our light raising and lowering practices are largely dictated by this technology. Still, our understanding of proper grow light positioning results from an array of sources.

Just 10-15 short years ago, singe-ended/air-cooled HPS lights were the “go-to” technology for cannabis growers. The “SE HPS era” gave rise to our current understanding of such important horticultural lighting concepts as PAR light and the inverse square law. This period also taught us to raise and lower our lights to maximize usable light for plant growth.

Many commercial growers today are reluctant to switch to LED lights due to the amount of labor needed to keep them properly positioned. In paying attention to this fact, the Minnesota-based company Lift and Grow has developed light lifting machines capable of working in a commercial capacity. Both Chris Watt and Mike Miller are Lift and Grow customers. For his part, Watt tells us Lift and Grow machines “save time and labor” and “will pay for themselves in a year.” Miller highlights the convenience of such systems, stating “all you need to do is hit a button and the lights move exactly where you want them to be.”

The financial perks of LED grow lights make them hard to ignore, even if the technology requires the laborious task of moving lights. The next few years will likely see the continued growth of LED lights in cannabis, with innovative companies like Lift and Grow joining forces with growers to help facilitate this technological shift.